ABOUT BONIFACE TOOL & DIE

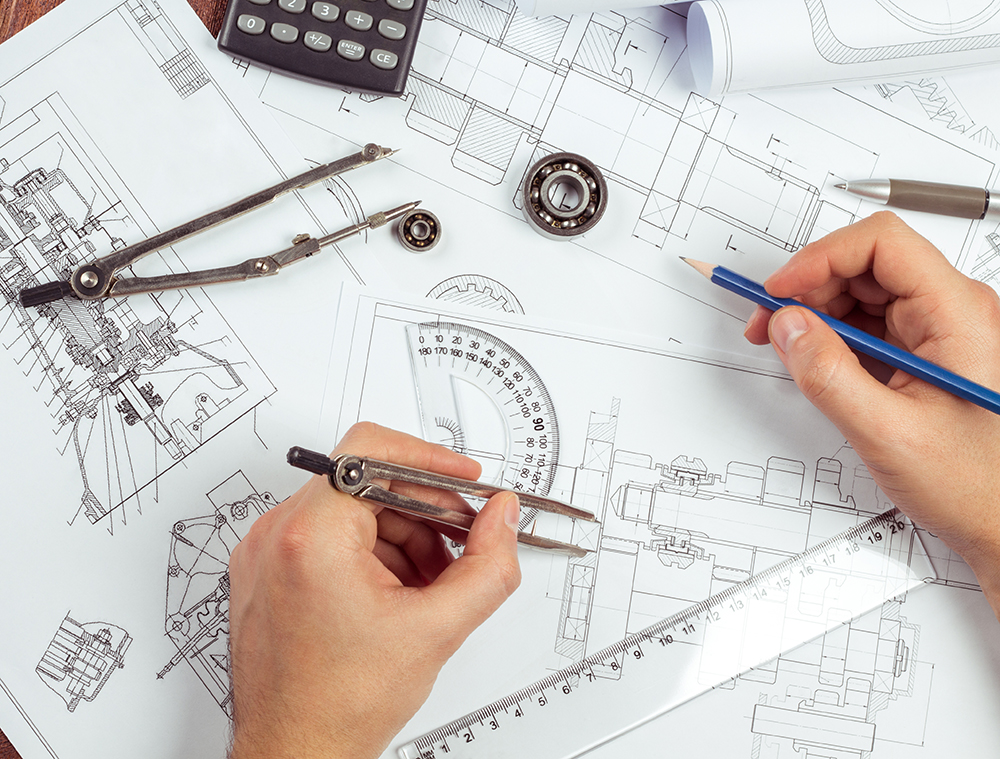

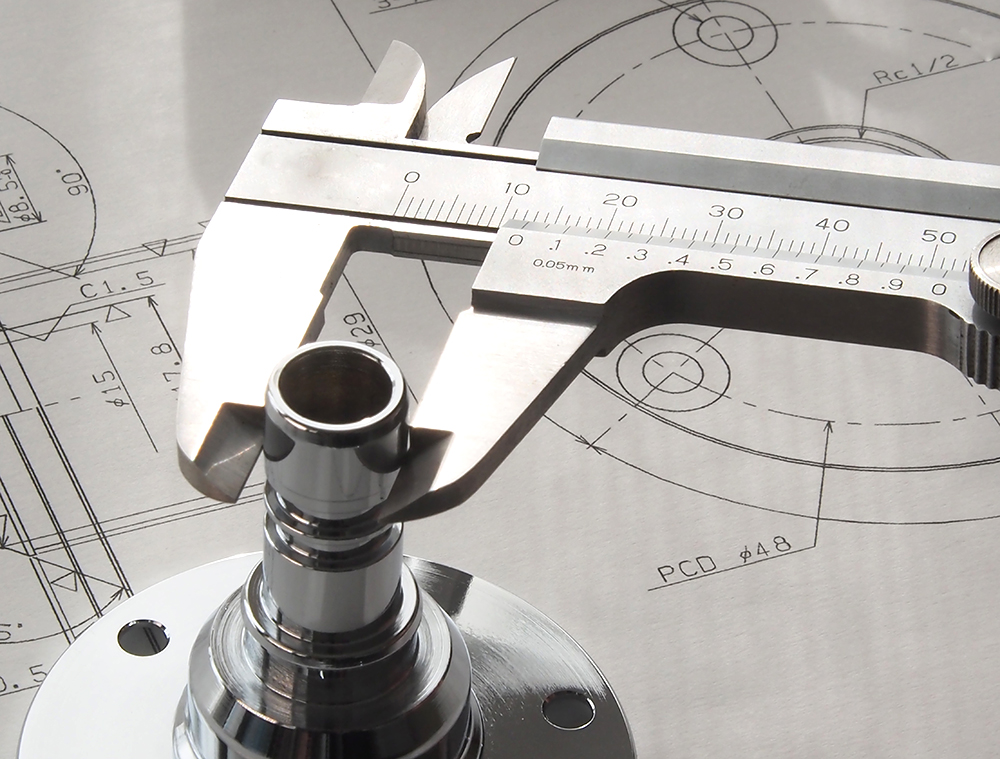

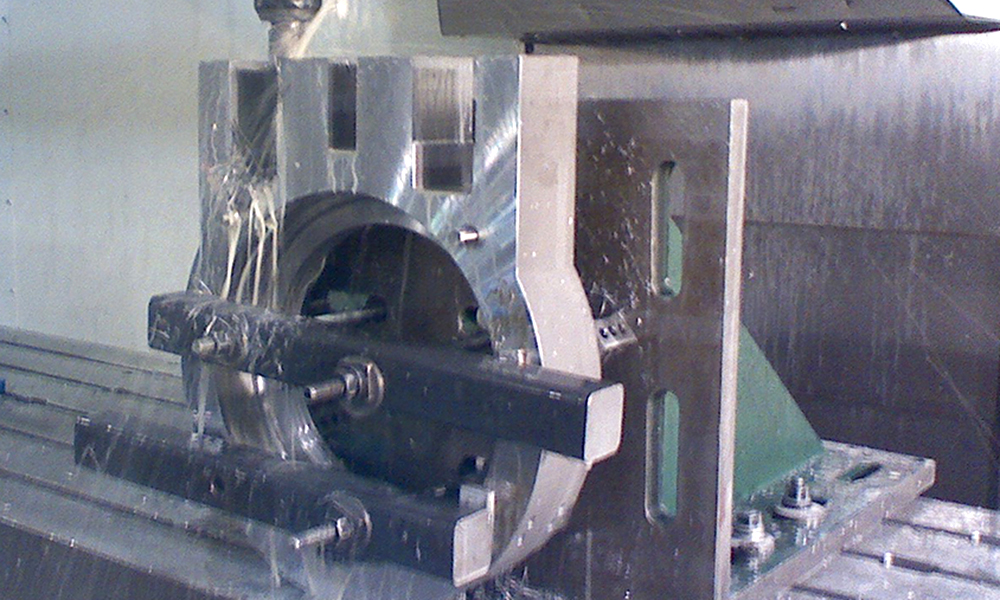

In 1957, Boniface Tool & Die began in the family garage. Today, Boniface Tool & Die operates state-of-the-art equipment, including two newly acquired tape milling machines. From a nearly 70,000 square foot facility in Dudley, Massachusetts, Boniface provides its customers worldwide with precision machined tools and components. While our equipment has changed and our company home has grown, our commitment to quality and customer satisfaction has remained the same.

Whether you require aircraft engine ground support tools and equipment, or machined parts for aerospace, naval, land based, or manufacturing industries, Boniface Tool & Die is your source for quality precision machined components. We have the ability to work on materials from plastics and nylon to alloy and super alloy metals.

Boniface Tool & Die has an ongoing commitment to improvement and a proven track record which speaks for itself. For over forty years, Boniface has stood the test of time. The service and capability which we offer in tool making and precision machining is deeply rooted in our history, longevity, and commitment to the future. We believe this combination will propel Boniface well into the next century and we look forward to sharing in business success with our customers.